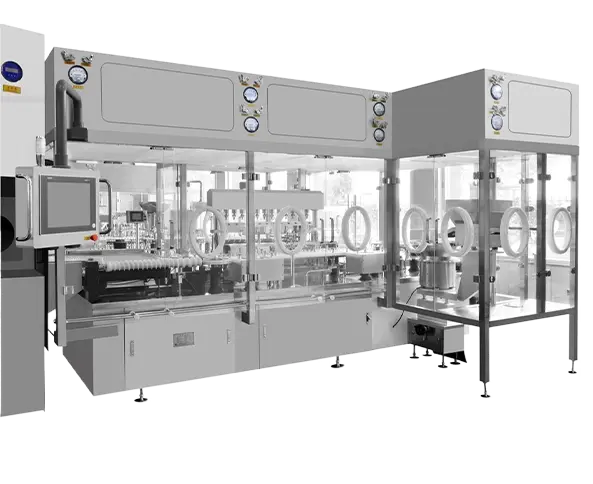

The machine adopts the PLC control with mechanical and electrical integration, and is provided with the functions of“no bottle no filling”and “no bottle no stoppering”. The machine surfaces are made of high quality stainless steel, which is conformed with the latest GMP requirements.

CN

CN