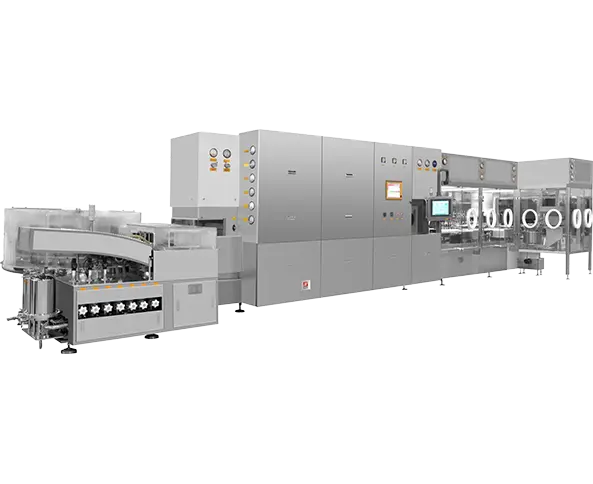

The vial washing machine adopts the mechanical arms to clamp the vials in various specifications;

The water-gas spray nozzles adopt the reciprocating tracking insertion mode for vial washing, featured by excellent washing effect and energy saving. It is also provided with a device that prevents the nozzle holder from shaking to enhance the accuracy of the spray nozzle's insertion into the vials and reduce the occurrence of nozzle breakage;

The water and gas pipes are totally separable from the spray nozzles, so that cross contamination is avoided and cGMP requirements are met;

The buffer block is installed before the vial out-feed scroll of the vial washing machine to protect the scroll and reduce vial breakage;

Vial out-feed is realized by the integral imported synchronous belt that is connected to the vial pushing block to convey ampoules, a structure that ensures stable and reliable transmission;

The depyrogenation tunnel adopts the hot air circulation heating method with even temperature and energy saving;

The depyrogenation tunnel is provided with the function of protecting against sudden power-off to ensure safe running;

The depyrogenation tunnel can be equipped with the water cooling device that does not consume air volume in the room, whilst reducing the risk of unbalanced differential pressure in the room and achieve good cooling effect;

The depyrogenation tunnel can be equipped with the differential pressure automatic balancing and regulating system to eliminate the issues of deviation at the high temperature section caused by unbalanced differential pressure in the room and tunnel, and the temperature rise in the filling room and washing-drying room;

The depyrogenation tunnel is provided with the PAO inspection ports (including inspection ports for air pressure, air speed and dust particles);

The cooling section in the tunnel is provided with the sterilization function (specially chosen by FDA);

The depyrogenation tunnel mesh belt can be equipped with the ultrasonic and CIP cleaning systems;

The depyrogenation tunnel chamber can be subject to all-round, multi-angle high pressure water washing;

The filling machine adopts the horizontal synchronous belt for vial transmission with high speed, accurate vial separation and convenient change-over of the format parts;

The conveying plane where the vial is positioned has a certain distance to the work bench to make the class 100 air flow easy to go pass smoothly, and to avoid the drug to be polluted by the turbulent air flow;

The stoppering part of the filling machine adopts the horizontal stopper feeding and plate suction systems, featured by convenient observation, easy material feeding and high stopper feeding speed;

The filling machine can be equipped with the ceramic pump, piston pump or peristaltic pump;

The filling machine is provided with the functions of no bottle no filling and no bottle no stoppering;

The filling machine can be equipped with the servo filling system.

Control system of brands such as Siemens, Schneider, Allen Bradley, Mitsubishi and Delta;

Online particle counting, alarm system, recording and printing systems;

ORABS, CRABS, or aseptic isolator system.

| Product Model | QCL60+ASMR620/35+KGF4 | QCL60+ASMR620/43+KGF6 | QCL60+ASMR620/43+KGF8 | QCL80+ASMR620/48+KGF10 | QCL120+ASMR800/55+KGF12 | QCL120+ASMR1250/60+KGF20 | QCL80*2+ASMR1250/60+KGF12*2 |

| Applicable Specifications (ml) (GB standard vial) |

2-25 | ||||||

| Number of Filling Heads | 4 | 6 | 8 | 10 | 12 | 20 | 24 |

| Production Capacity (pcs/min) | 120 (2ml) | 180 (2ml) | 200 (2ml) | 300 (2ml) | 400 (2ml) | 500 (2ml) | 650 (2ml) |

| Qualified Rate of Bottle Washing (%) | ≥99 | ||||||

| Breakage Rate of Washing (%) | ≤0.1 | ||||||

| Sterilization Temperature (°C) | 300-500 | ||||||

| Exhaust Air (m2/h) | 3,000 | 4,100 | 7,500 | 8,000-10,000 | |||

| Flling Accuracy (%) | ≤±2.5 (Mechanical control of fling pump) ≤±0.5-1.0 (Servo contro of fling pump) |

||||||

| Qualifed Rate of Stoppering (%) | ≥99 | ||||||

| Cleanliness of Laminar Air (Class) | 100 | ||||||

| Speed of Vacuum Pumping (m3/h) | 10 | 30 | 50 | 60 | 60 | 100 | 120 |

| Capacitance (kw) | 66.6 | 75.6 | 106.6 | 212.6 | 232.6 | ||

| Power supply | 385V/50Hz | ||||||

| Total weight (kg) | 6,300 | 6,300 | 7,900 | 9,400 | 10,900 | 14,600 | |

| Dimension (LxWxH) (mm) | 8,550 × 2,540 × 2,330 | 9,620 × 2,540 × 2,330 | 10,280 × 3,230 × 2,360 | 12,730 × 2,600 × 2,620 | 11,790 × 5,700 × 2,620 | ||

WANT TO KNOW MORE ABOUT HOW OUR

SOLUTIONS CAN HELP YOU?