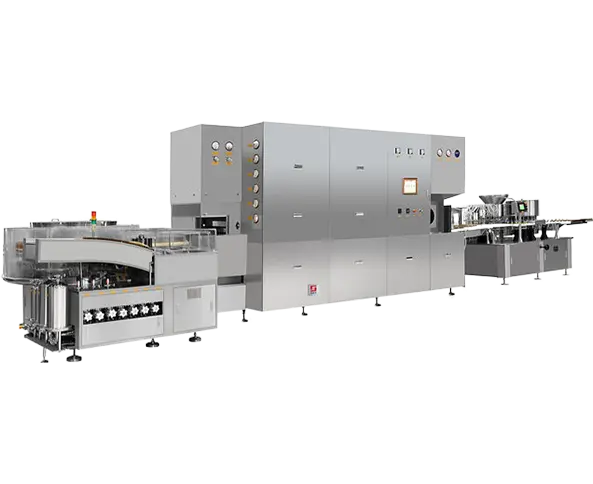

The washing machine adopts the mechanical arms to clamp the oral liquid containers of 2-25ml;

The water-air spray nozzles adopt the reciprocating tracking insertion method for washing, featured by excellent washing effect and energy saving. It is also provided with a device that prevents the nozzle holder from shaking to enhance the accuracy of the spray nozzle's insertion into the ampoule and reduce the occurrence of nozzle breakage;

The water and air pipes are totally separable from the spray nozzles, so that cross contamination is avoided and cGMP requirements are satisfied;

The buffer block is installed before the ampoule out-feed scroll for the washing machine to protect the scroll and reduce breakage;

The depyrogenation tunnel adopts the hot air circulation heating method with even temperature and energy saving;

The depyrogenation tunnel is provided with the function of protecting against sudden power-off to ensure safe running;

The depyrogenation tunnel can be equipped with the water cooling device that does not consume air volume in the room, which can reduce the risk of unbalanced differential pressure in the room and achieve good cooling effect;

The depyrogenation tunnel can be equipped with the differential pressure automatic balancing and regulating system to eliminate the issues of deviation at the high temperature section caused by unbalanced differential pressure in the room and tunnel, and the temperature rise in the filling room and washing-drying room;

The depyrogenation tunnel is provided with the PAO inspection ports (including inspection ports for air pressure, air velocity and dust particles);

The cooling section in the tunnel is provided with the sterilization function (specially chosen by FDA)- optional;

The depyrogenation tunnel mesh belt can be equipped with the ultrasonic and CIP cleaning systems;

The depyrogenation tunnel chamber can be subject to all-round, multi-angle high pressure water washing;

The filling-sealing machine can be equipped with the ceramic pump and stainless steel pump;

The filling-capping machine is provided with the functions of no bottle no filling and no bottle no capping.

Control system of brands such as Siemens, Schneider, Allen Bradley, Mitsubishi and Delta;

Online particle counting, alarm system, recording and printing systems;

ORABS, CRABS, or aseptic isolator system.

| Product Model | QCL100+ASMR620+YGZ16 | QCL140+ASMR620+YZG24 |

| Applicable specifications (ml) | 2-25 | 2-20 |

| Production capacity (pcs/min) | 350-400 | 400-600 |

| Number of filling heads | 16 | 24 |

| Number of capping heads | 20 | 20 |

| Gross weight (kg) | 7,500 | |

| Overall dimensions (mm) | 9,920 × 2,003 × 2,150 | |

WANT TO KNOW MORE ABOUT HOW OUR

SOLUTIONS CAN HELP YOU?