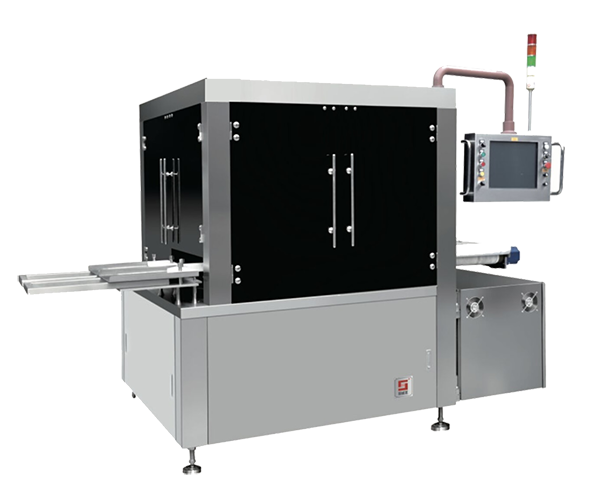

The machine visual principle is adopted. The sequential images of ampoules are captured by three groups of high speed industrial cameras and sent to the industrial computer for automatic detection of visible impurities and separation of nonconforming products;

Light reflection imaging and light transmission imaging are adopted for detection of visible impurities;

Cosmetic detection with optical imaging facility is applied for checking the ampoule tip quality and carbonization defects;

The full-servo transmission system is adopted to ensure high speed, stable and precise running;

The advanced industrial computer system is adopted to monitor the running status of the equipment in a real-time manner and realize remote diagnosis;

Components of world famous brands are adopted, including cameras, lens, light sources, servo motors, and so on;

Customized LED light sources and strobe control technology are adopted to prolong the service life of light sources;

Provided with the function of bottle rotation speed online monitoring.

| Product Model | ABJ66 | ABJ90 |

| Container type | Ampoules, Vials, Oral liquid bottles | Ampoules, Vials, Oral liquid bottles |

| Number of bottles holders | 66 | 90 |

| Applicable specification (ml) | 1-30 | 1-10 |

| Capacity (bpm) | 400 | 600 |

| Power (kw) | 9 | 11 |

| Power Supply | 380V/50Hz | 380V/50Hz |

| Noise (DB) | < 75 | < 75 |

| Air pressure supply (mpa) | 0.5-0.7 | 0.5-0.7 |

| Overall dimensions (LxWxH) (mm) | 2,740 x 1,520 x 1,500 | 3,400 x 2,540 x 2,730 |

| Weight (kg) | 2,500 | 2,800 |

WANT TO KNOW MORE ABOUT HOW OUR

SOLUTIONS CAN HELP YOU?