Home > Products > STAND-ALONE MACHINES >

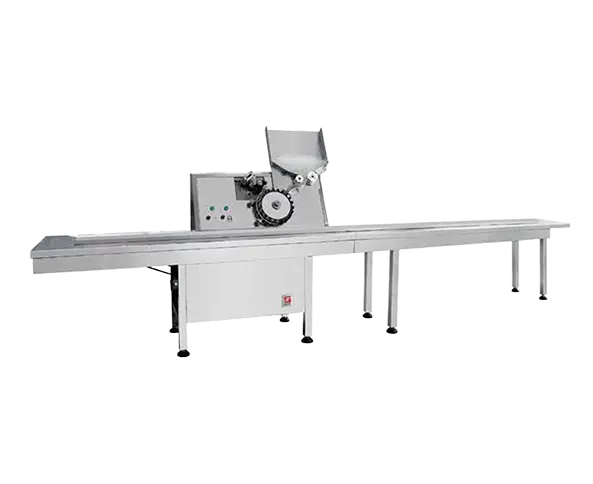

| Appicable Ampoule Specifications (ml) | 1, 2, 5, 10, 20 |

| Production Capacity (pcs/hr) | 15,000-30,000 |

| Engine Power | 22V 100W |

| Dimension (LxWxH) (mm) | 4,300 x 600 x 1,580 |

| Weight (kg) | 170 |

| Rotating-disk Printer | ||

| Bottle Feeding |

(1) The inclination of feeding is small, and makes it easy to feed ampoules; (2) Rotary-type feed hooper is easy to convey ampoules and can avoid diflection. |

(1) The inclination of feeding is large, which makes it difficult to feed ampoules; (2) Push-plate type feed hopper is easy to be skewed. |

| Letter Printing |

(1) Printing can be on the turntable, and the writing is clear and will not be blurred. The printing range is large with maximum 5 rows; (2) Bottle-type structure, and letter font type, drug name version is easy to replace. R is correct, the font size is consistent, and the printing is not shallow. Good printing quality ensured; (3) 1-20ml ampoules can be printed in the same machine with format parts, and parts are easy to be changed over; |

(1) Printing on the sponge is easy to blur. The printing range is small with only 3 rows; (2) Roller type structure, and letter fonts and plates cannot be shared. R is hand-molded and is inaccurate, the writing is shallow, and the quality of the printing is difficult to guarantee; (3) 1-20ml ampoule can not pass, can only be divided into three models. |

| Bottle Unloading | Rotary feeding makes ampoules in order and easy to enter the carton with successful rate of more than 98%. | Projective feeding makes ampoules difficult to enter the carton with successful rate of only 80-90%. |

| Adding Printing Ink | Automatic printing ink injection device is designed to automatically add printing ink. Ink adding times will be greatly reduced with well proportioned printing ink effect. | No device for ink injection with frequent manual ink injection and the printing ink will be uneven. |

WANT TO KNOW MORE ABOUT HOW OUR

SOLUTIONS CAN HELP YOU?